What is the 5S System? How to Apply it in Factories

January 22, 2026 07:10 AM

In an industrial production environment, maintaining a tidy, clean, and safe workplace plays an important role in improving productivity while contributing to minimizing risks and operating costs. To improve operational efficiency, many businesses have chosen to apply lean management methods. Among them, the 5S system is considered a basic foundation, easy to deploy, and brings […]

In an industrial production environment, maintaining a tidy, clean, and safe workplace plays an important role in improving productivity while contributing to minimizing risks and operating costs. To improve operational efficiency, many businesses have chosen to apply lean management methods. Among them, the 5S system is considered a basic foundation, easy to deploy, and brings tangible results in reality.

1. What is the 5S System?

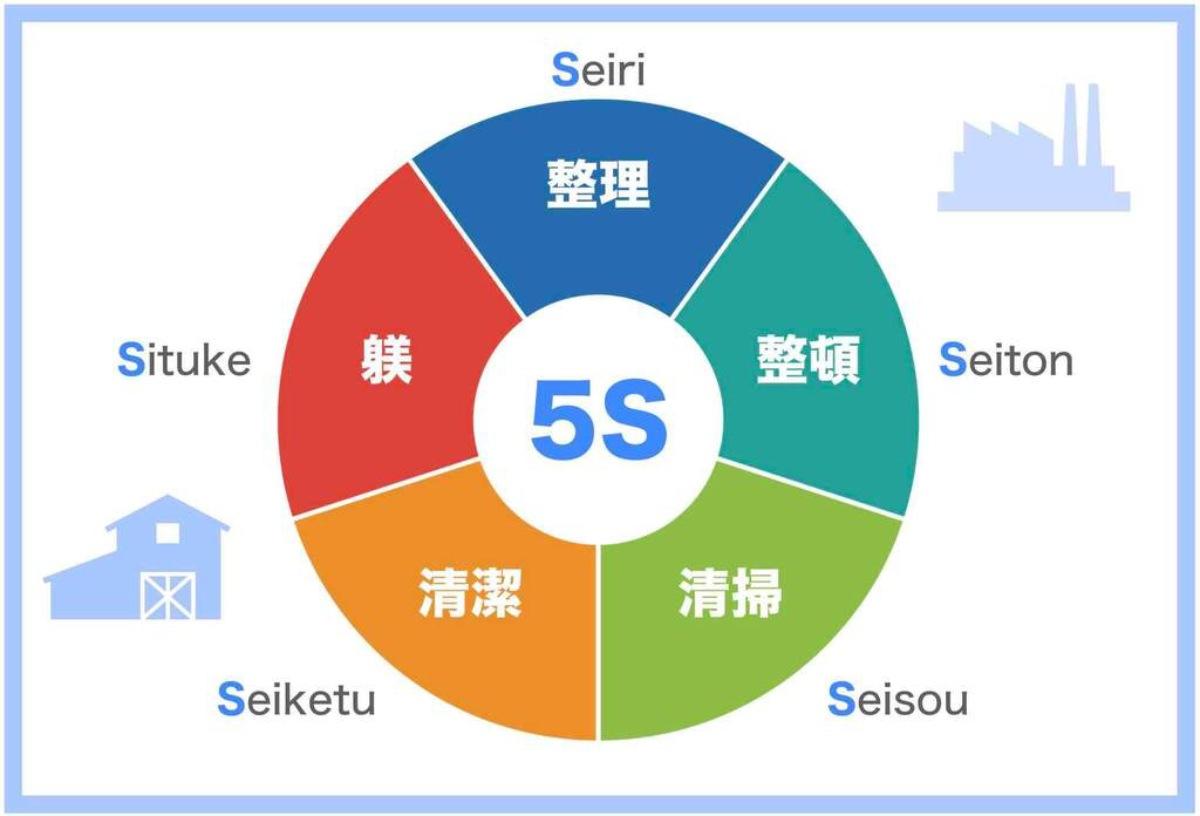

The 5S system is a workplace management and organization method originating from Japan. 5S stands for 5 Japanese words, each starting with the letter “S”:

- Seiri (Sort – Sàng lọc): Removing unnecessary items.

- Seiton (Set in order – Sắp xếp): Organizing necessary items efficiently.

- Seiso (Shine – Sạch sẽ): Cleaning the workplace.

- Seiketsu (Standardize – Săn sóc): Maintaining high standards of housekeeping.

- Shitsuke (Sustain – Sẵn sàng): Developing self-discipline and sustaining the system.

The goal of 5S is to create an effective, safe, and tidy working environment, helping to improve productivity and work quality.

5S System Model.

2. Benefits of Applying 5S in Industrial Factories

The benefits that the 5S method brings are very clear, especially in an industrial factory environment. From optimizing space to improving productivity and ensuring safety, this system has proven its essential role in modern operations.

2.1. Optimizing Workspace

The scientific screening and arranging process in the 5S system helps the factory free up area as well as reorganize the production floor more effectively. Instead of letting materials and tools lie scattered or piled up in warehouse corners, applying the 5S system will help everything be clearly classified, keeping only necessary items and arranging them reasonably according to each functional area. Thanks to that, the workspace becomes airy, movement flow between stages is shortened, minimizing collisions and safety risks. The material search process is also significantly shortened, contributing to increasing operation speed and improving operational efficiency.

Optimizing workspace after using the 5S system.

2.2. Increasing Labor Productivity

When the 5S system is applied effectively, all tools and materials are arranged in fixed, clear positions, so workers will not have to waste time searching or borrowing back and forth; the production process thus takes place quickly and seamlessly, with few interruptions. At the same time, machinery is cleaned and inspected periodically, contributing to maintaining stable operation status and minimizing the risk of interruption due to breakdowns. All these factors contribute directly to increasing the labor productivity of the entire system.

2.3. Reducing Accident Risks and Production Errors

Building a tidy, clean production environment according to 5S standards helps significantly reduce occupational safety risks such as slipping, tripping over wires, or contact with sharp objects… On the other hand, regular cleaning and inspection of machinery helps detect potential technical incidents early to promptly offer response solutions before affecting the production line.

2.4. Enhancing Corporate Culture

Applying and deploying the 5S system means building a working environment based on discipline, tidiness, and a sense of responsibility. When each individual actively maintains the habit of sorting, arranging, and preserving the workspace, a culture of self-discipline will gradually form. Coordination between departments also becomes more effective and harmonious thanks to clear processes and scientifically organized space. Over time, these small but persistent actions will contribute to shaping a positive, stable, and sustainable corporate culture. This is the foundation for a positive, sustainable, and professional working environment following a long-term development orientation with the unique identity of each organization.

3. Steps to Effectively Deploy 5S in Factories

To deploy the 5S method methodically, businesses need to follow 5 foundational steps sequentially. Each step is an indispensable part of establishing a scientific workspace, promoting labor discipline, improving performance, and limiting resource waste throughout the entire production process.

3.1. Step 1: Seiri (Sort) – Eliminate unnecessary items

The first step in the 5S process is to remove unnecessary items from the workplace to ensure only items truly necessary for work remain. Things not needed for work such as outdated documents, broken machinery, or inventory materials with unclear purposes need to be processed promptly to create an airy workspace, easy for operation and work management.

3.2. Step 2: Seiton (Set in order) – Establish rules for arranging materials and machinery

After removing excess items, the next step is to arrange the remaining items reasonably for convenient use. In the 5S method, each tool and equipment needs a fixed position and clear labeling, demonstrating logic and visuality. This can be done by zoning functions, using location diagrams, and arranging specialized shelves.

3.3. Step 3: Seiso (Shine) – Plan periodic cleaning

The 5S system refers to maintaining a constantly clean working environment by regularly cleaning and inspecting machinery and equipment to improve image and ensure production safety. This step includes regularly cleaning machinery, wiping the work area, and checking for potential hazards such as oil leaks, metal dust, or working equipment… This is a factor that not only brings a comfortable workspace but also helps detect potential incidents such as damage or leaks early, thereby improving equipment safety and durability.

3.4. Step 4: Seiketsu (Standardize) – Maintain and standardize the 5S process

When the first three steps have formed a foundation, businesses need to standardize processes to maintain stability and consistency. Visual instruction boards, standard layout diagrams, and periodic inspection forms are useful tools to help all personnel comply with 5S principles consistently. Standardize is the step of maintaining standards and routines in 5S practice, ensuring stability and consistency throughout the entire process.

3.5. Step 5: Shitsuke (Sustain) – Build self-discipline awareness in all employees

The final step in the 5S method is to maintain discipline and form a habit of self-discipline throughout the organization. Without regular training, 5S will easily become an initial form and then fade away. Conversely, when each individual clearly understands their role in preserving the working environment, overall efficiency will be maintained sustainably. Businesses can build emulation assessment mechanisms, organize periodic training, and integrate 5S into internal culture to ensure the long-term nature of the system. This is the key factor for the 5S system to truly be effective sustainably.

4. Important Notes When Deploying 5S

Although the 5S method has a simple structure and is accessible, to deploy successfully and maintain sustainably in factory reality, businesses need to pay attention to some core factors.

4.1. The Role of Leadership

Leaders play a key role in orienting, deploying, and maintaining the 5S system effectively. Commitment and exemplary behavior from management will create motivation and trust for all employees during implementation. Leaders need to directly participate in the 5S deployment process through periodic supervision, timely feedback, and setting examples in daily practice. The active presence of management is a way to build trust and promote a spirit of self-discipline as well as commitment from all employees.

4.2. Periodic Personnel Training

Training is necessary to ensure every employee correctly understands the nature and benefits of 5S, thereby forming a habit of self-discipline instead of coping. Training content needs to focus on how to perform each 5S step in a practical work context, combined with updating new improvements over time to suit the production situation. Especially, new personnel need to be trained from the start to ensure consistency throughout the system.

Training to guide the implementation of 5S system practice.

4.3. Continuous Assessment and Improvement

Implementing the 5S model is not a one-time activity but requires maintaining periodic checks, regular assessments, and continuous adjustments. Businesses should build specific internal 5S assessment criteria tables, conduct periodic checks (weekly/monthly), and provide timely feedback combined with handling non-conformities promptly. Besides, encouraging employees to propose improvements is also an effective way for the system to become increasingly perfect and better adapted to production reality.

5. Practical Models Successfully Applying 5S

In reality, many businesses in different fields such as FDI, electronic component manufacturing, or mechanical engineering – steel structures have deployed 5S effectively, bringing clear improvements in production organization, quality, and working environment.

5.1. FDI Enterprises in Industrial Parks

In the context of global competition and high requirements from the supply chain, many foreign-invested enterprises (FDI) in Vietnam have applied the 5S system as an advanced production management foundation. 5S both helps optimize the work floor and creates a professional labor culture, improves productivity, and effectively controls quality. A proof is Thanh Long Electronic Production Joint Stock Company – an FDI enterprise operating in the field of manufacturing electronic components, with a factory in an industrial park in Northern Vietnam. Initially a tier-2 supplier for large corporations like Samsung, after synchronously deploying the 5S system combined with Kaizen, the company quickly improved the working environment and enhanced production capacity.

5.2. Electronic Component Manufacturing Factory

For environments requiring high precision and strict hygiene conditions like electronics manufacturing, the 5S model becomes a useful system applied to control errors, shorten operation time, and ensure stable output quality.

Specifically, Hanoi Plastics Joint Stock Company, specializing in high-tech plastic component manufacturing, has applied the 5S system combined with Kaizen throughout the factory. Employees are trained periodically on 5S, production areas are clearly zoned, materials are scientifically organized, easy to identify, fast to operate, and convenient during use…

Hanoi Plastics Joint Stock Company implements the 5S system.

5.3. Mechanical Workshop – Steel Structure

In mechanical workshops – steel structures, production characteristics involve large volumes of materials, bulky machinery, dusty environments, grease, and high potential risks of occupational accidents. For such a working environment, the 5S system is an effective way to help organize the production floor reasonably, playing an important role in ensuring safety, increasing productivity, and improving the professionalism of the working environment.

For example, Hoa Phat Group – one of the largest heavy industrial manufacturing enterprises in Vietnam, has applied the 5S system at the Hoa Phat – Dung Quat Iron and Steel Production Complex. Since 2014, the group has established a Steering Committee to deploy 5S, built specific organizational plans and regulations for each unit, and simultaneously launched emulation movements to implement 5S throughout the complex.

Conclusion

In the context of industrial transformation and increasingly strict standards, the 5S system becomes an indispensable part for factories to aim for stability, professionalism, and sustainable development. Each step in the 5S method from “Sort” to “Sustain” contributes to changing work habits, reducing waste, and comprehensively improving productivity.

Warehouse for lease in Vietnam | Warehouse for rent in Vietnam | Factory for lease in Vietnam | Factory for rent in Vietnam