How to optimize factory space?

September 04, 2024 07:56 AM

In the rise of industrial development, optimizing space within factories has become a crucial factor for enhancing production efficiency and reducing operating costs. This article will present methods and strategies for optimizing factory space, including rational layout design and the application of modern technology, to help businesses maximize operational efficiency. 1. The situations for reduction […]

In the rise of industrial development, optimizing space within factories has become a crucial factor for enhancing production efficiency and reducing operating costs. This article will present methods and strategies for optimizing factory space, including rational layout design and the application of modern technology, to help businesses maximize operational efficiency.

1. The situations for reduction in workspace area

How to balance space optimization and safety?

Understanding the causes of reduced factory space helps businesses to carry out space optimizing solutions, thereby easily improving productivity and efficiency of labor, saving costs.

1.1 Expansion of business activities and production

After a period of successful business operations, most companies tend to expand their industries and production scales. To meet the increasing demands of customers, businesses need to invest in additional machinery, equipment, and raw materials. However, this reduces the available factory space, so it needs to expand floor area to organize new production activities.

1.2 Ineffective inventory management policies

Nowadays, businesses are having many difficulties with inventory management policies and inefficient management. This can cause many problems such as overstocking goods and raw materials, affecting not only storage spaces but also creating more difficulties in inventory management which leads to overflowing, reducing available workspaces for other production activities.

1.3 Inefficient use and arrangement of workspace

When workspaces are not effectively optimized, many problems and fees can happen. There are two main reasons for this:

- First design of the factory was not optimized, making ineffectively use workspaces.

- Businesses have no knowledge about utilizing and managing factory’s inside space. Including the failure to use equipment with integrated and smart designs to maximize space efficiency.

2. Benefits of optimizing industrial factory workspace

Workspace optimization in industrial factories brings many important and practical benefits.

Firstly, reasonable space arrangement helps increase productivity. When workers and employees have a tidy, organized workspace, they can perform tasks more effectively, minimizing time spent moving around and searching for tools or materials. This solution not only boosts productivity but also contributes to improving production schedules.

Why should we apply space optimization methods in factories?

Additionally, space optimization also improves workplace safety. When workspaces, aisles and storage are tidily arranged, the risk of workplace accidents is reduced. A safe workplace environment not only protects the health and safety of employees, it also reduces fees related to workplace accidents and legal issues.

Optimizing space also means optimizing production lines. When working areas are reasonably organized, workflow will be smoother, reducing wastes and increasing production effectiveness. Production process is reasonably organized and will save time, resources and enhance product quality.

Benefits of a streamlined process in production activities

In addition, using space efficiently helps businesses save costs. Instead of renting more space or expanding industrial factories, businesses can maximize current space, helping reduce costs from renting and construction. Additionally, good space organizations help save energy, resources and contribute to lower operating costs.

Another benefit of optimizing space in factories is enhancing the professional and credibility of the business. An tidy, organized and safe industrial factory will leave a positive impression on visiting partners, thereby elevating business’s image and credibility.

Furthermore, a safe and comfortable working environment will attract talents, help businesses with high-quality teams, contributing to sustainable development and long-term success.

3. Six methods to optimize workspace in factories and plants

3.1 Applying lean manufacturing principles to factory layout

Lean manufacturing focuses on eliminating waste and optimizing production processes. Applying these principles to factory layout includes:

- Reorganize production process: Ensure all the processes are organized in a flow, from raw materials to final products.

- Minimize movement: Arrange machines and equipment nearly to reduce unnecessary movement of materials and products.

- Implementing 5S system: Sort, Set in Order, Shine, Standardize and Sustain, creating a tidy and effective working environment.

Applying lean principles in production lines

3.2 Reducing the width of aisles

Reducing width of aisles in industrial factories is an effective solution to optimize workspaces. However, this optimization needs to be done carefully to ensure safety and effectiveness.

Firstly, we need to consider movement requirements in the factory to identify which aisles can be narrowed down without affecting the working process and safety. Using smaller transportation methods, such as trolleys or forklifts, can help to utilize small pathways and still ensure goods transportation effectiveness.

Additionally, optimize aisles organization to reduce movement distances, thereby utilize space for production and storing.

3.3 Using appropriate equipment and storage systems

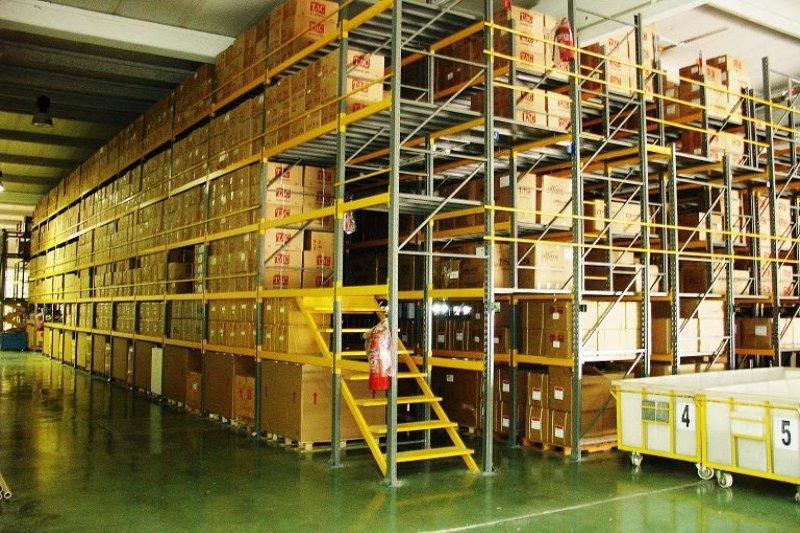

By implementing some advanced solutions such as multi-tier racks, mobile storage systems, businesses can utilize maximized area by heights, increasing storage capability without covering more floor area.

- Using multi-tier racks to maximize space in height, increasing storage capacity without additional floor space.

- Implementing mobile storage systems, flexible to arrange and organize space when necessary.

- Using a mobile tool cabinet not only optimizes space but also provides flexibility in movement, helping workers save time when transporting machinery and materials.

Using equipment to support industrial factory space optimization

3.4 Modifying the material handling system of the plant

Automatic transportation process is a key solution to optimize factory’s space. By using picking robots or forklifts, electric hoists, help minimize spaces needed for storage and materials transportation without using conveyor belts and bulky rail cars which will occupy the floor area despite being limited and inflexible functionality.

3.5 Installing mezzanine floors

Installing mezzanine floors is an effective solution to increase usable areas in factories without expanding the outside area. Mezzanine floors can be used to store goods, an office or working area, and utilize the factory’s height. This not only increases usable area but also increases workflow and production processes.

3.6 Removing and disposing of unused goods and materials

In the industrial factoríes operation process, storing goods and materials without any uses is inevitable. Because of that, sorting and ejecting these goods will optimize the factory’s space.

- Inventory and appraisal: Occasional inventory used to identify which goods will be ejected, unnecessary or unused materials.

- Efficient inventory management: Implement inventory management methods such as EOQ, POQ, QDM, ABC models effectively to minimize inventory levels and free up space.

- Liquidation and recycling: Sell or recycle unused materials and goods to create additional space for industrial warehouses and contribute to environmental protection.

Consulting construction experts to optimize smart factory space while saving costs

Conclusion

Optimizing industrial factory space is an opportunity for businesses to enhance competitiveness and achieve sustainability in today’s increasingly competitive market. From reducing warehouse rental costs, and transportation expenses to enhancing corporate image,… all contribute to the long-term strategic development and success of businesses.

When businesses need to rent a warehouse at Gaw NP Industrial, immediately contact Hotline +84 789 75 77 88 for detailed advice.

See more:

>> Discover the key factors for selecting the ideal factory for rent in Vietnam

>> Uncover the advantages of renting a factory with office space in Vietnam

Warehouse for lease in Vietnam | Warehouse for rent in Vietnam | Factory for lease in Vietnam | Factory for rent in Vietnam