How to design and arrange warehouse to achieve operational efficiency for business

September 06, 2024 07:01 AM

A reasonable design and layout of a warehouse is a crucial factor in helping businesses to save costs and improve operational efficiency. Optimizing storage space, reducing search and transport time will enhance productivity and business efficiency. In the following article, let’s learn about effective warehouse design experiences. 1. The reason for necessity to arrange the […]

A reasonable design and layout of a warehouse is a crucial factor in helping businesses to save costs and improve operational efficiency. Optimizing storage space, reducing search and transport time will enhance productivity and business efficiency. In the following article, let’s learn about effective warehouse design experiences.

1. The reason for necessity to arrange the warehouse scientifically

Optimizing warehouse space through scientific layout is the key to enhancing operational efficiency and minimizing operating costs. By arranging goods effectively, businesses can maximize warehouse space, eliminate wasted space. This not only improves workflow and saves time but also minimizes the risk of damage and loss of goods, ensures employee safety.

A properly arranged warehouse also contributes to improving customer service quality, making a professional and reliable impression. Investing in scientific warehouse layout is not only a cost-saving measure but also a long-term strategy to enhance a business’s competitiveness in the market.

Scientific warehouse arrangement optimizes storage space

With many benefits in optimizing warehouse space, employees can easily find, retrieve, and inventory goods, minimizing time and effort. Optimizing space and workflow helps reduce costs related to warehouse management, storage, and labor. Rational organization of goods helps reduce the risk of workplace accidents and damage to goods. Achieving efficiency in space optimization makes order picking more convenient, fast and accurate deliveries, which will increase customer satisfaction.

2. Instructions on how to optimally arrange warehouses for businesses

2.1 Using SKU codes

SKU (Stock Keeping Unit) codes are numbers or characters representing each type of product in the warehouse. Using SKU codes helps businesses to manage goods easily, locate products quickly, and track inventory accurately. With SKU codes, the process of inventory and goods management becomes much simpler, minimizing errors and increasing work efficiency.

2.2 Zoning areas and creating a complete warehouse layout

Zoning and creating a warehouse layout are essential steps to optimize space and manage goods. When categorizing products, businesses should consider the nature, frequency of use, size, and weight of each type.

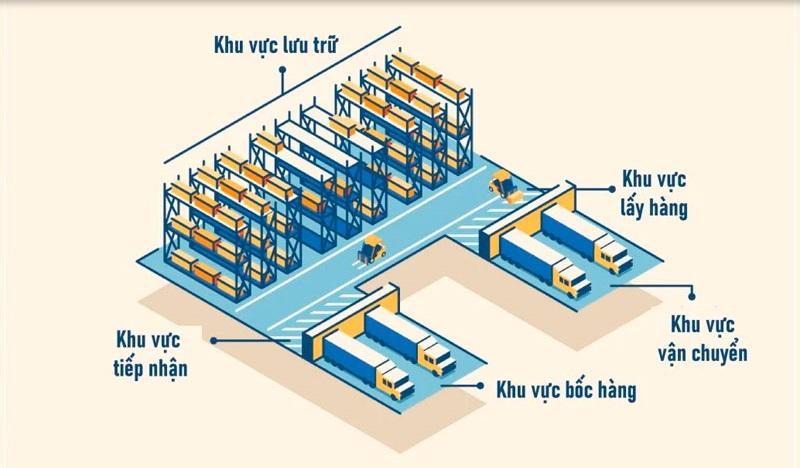

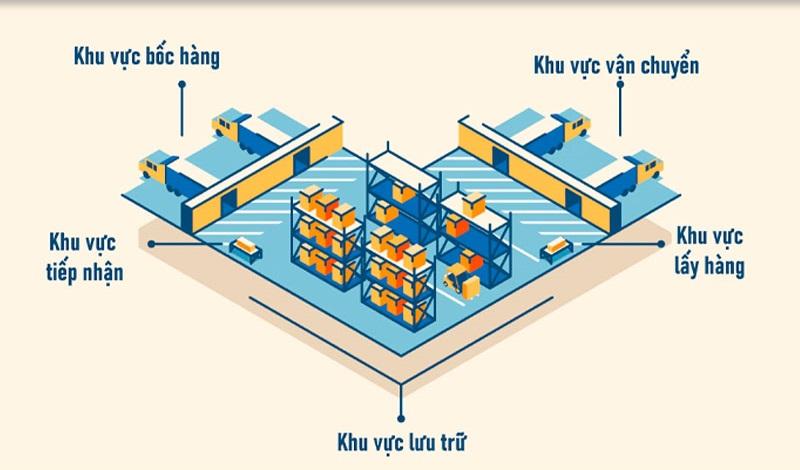

The main areas in the warehouse should be clearly defined, including receiving, storage, packing, and shipping areas. This makes managing and moving goods easier and more efficient. Additionally, attention should be paid to utilities and safety, ensuring spacious aisles, easy movement, and fire prevention measures.

There are three common warehouse layout models:

- U-shaped layout

- I-shaped layout

- L-shaped layout

The U-shaped layout is available for small warehouses, optimizing movement space and making management easier.

The I-shaped layout is suitable for long and narrow warehouses, creating a straight path from begin to end, facilitating convenient movement.

The L-shaped layout is used for irregularly shaped warehouses, optimizing corner space and efficiently utilizing the area.

2.3 Applying the principle of arrangement appropriately

Applying the principle of arrangement is essential to ensure efficient warehouse management.

- The FIFO (First In, First Out) means that first goods will be shipped immediately, helping to avoid spoilage and expiration.

- The LIFO (Last In, First Out) means that last goods will be shipped immediately, available for items without expiration dates.

- Additionally, the ABC principle classifies goods based on their value and frequency of use to arrange them logically, optimize the management process.

Applying the principle of stock to improve warehouse efficiency

2.4 Using suitable warehouse shelving

Not only space arrangement, but selecting and using suitable warehouse shelving also plays a crucial role in optimizing warehouse operations. Pallet racks are an available solution for storing heavy and bulky goods, maximizing floor space utilization. Shelving allows for taking advantage of the height of the warehouse, saving floor space and increasing storage capacity. For warehouses requiring flexibility, flexible shelving is an optimal choice, allowing easy movement and access to goods when needed.

Combining different types of warehouse shelving scientifically will create an efficient storage system, meeting business needs and optimizing warehouse space.

Using suitable shelving brings many benefits to businesses

Each industry and business has different storage needs, so companies should thoroughly research specialized shelving for their specific sector.

2.5 Installing signage

Installing signage in the warehouse is an essential step to ensure smooth and safe operations for employees. Signage not only helps staff navigate and locate goods easily but also establishes a professional work environment and complies with safety regulations.

Types of signage can include, but are not limited to, location signs, safety signs, equipment usage instructions, and goods information signs. Each sign should be designed clearly, be easy to read, and be placed in a visible and logical location for easy observation.

Signage is clearly designed and easy to read

Signage is not only necessary but also compulsory for businesses operating warehouses. It ensures that everyone entering the warehouse is properly guided and performs the correct functions for each area. This helps avoid the risk of property damage and impacts on the health of workers while working in the warehouse.

3. Important considerations to avoid when arranging a warehouse

To arrange a warehouse reasonably and systematically, serving the effective transportation of goods, businesses should learn about various scientific methods of organizing goods to make warehouse operations more efficient. There are several things to keep in mind when arranging a warehouse that businesses should pay attention to.

Warehouse arrangement requires attention to ensure efficiency and safety

To ensure safety and efficiency in the warehouse, the arrangement of goods must follow these principles:

- Do not obstruct systems: Ensure that goods do not block the view of cameras, impede the airflow of ventilation systems, or hinder air conditioning.

- Place fragile items in a safe, separate area with clear warning signs and away from walkways to minimize the risk of collision.

- Never exceed the allowable load capacity of shelves to prevent collapses and ensure the safety of everyone.

- Prohibit cooking in the warehouse and do not place flammable goods near heat-emitting devices or electrical cabinets.

- Arrange goods neatly without encroaching on walkways to avoid obstacles and breakages, while creating a dry, airy, and aesthetically pleasing space.

- Implement regular inventory checks and always adhere to scientific arrangement principles.

Adhering to these principles not only ensures safety but also enhances the efficiency of warehouse operations.

Conclusion

Scientific warehouse arrangement is a key factor that helps businesses optimize space, increase work efficiency, and ensure safety. By using SKU codes, zoning areas, applying stocking principles, using suitable shelving, and installing signage, businesses can manage their warehouses more effectively. Avoiding basic mistakes in warehouse arrangement will help businesses save costs and improve service quality.

>>> See more: Explore the top 4 most popular types of industrial factories shaping today’s market

Warehouse for lease in Vietnam | Warehouse for rent in Vietnam | Factory for lease in Vietnam | Factory for rent in Vietnam